Metal processing is an excellent application for low-speed pulverizing technology.Qiansen has many metal processing customers around the world.

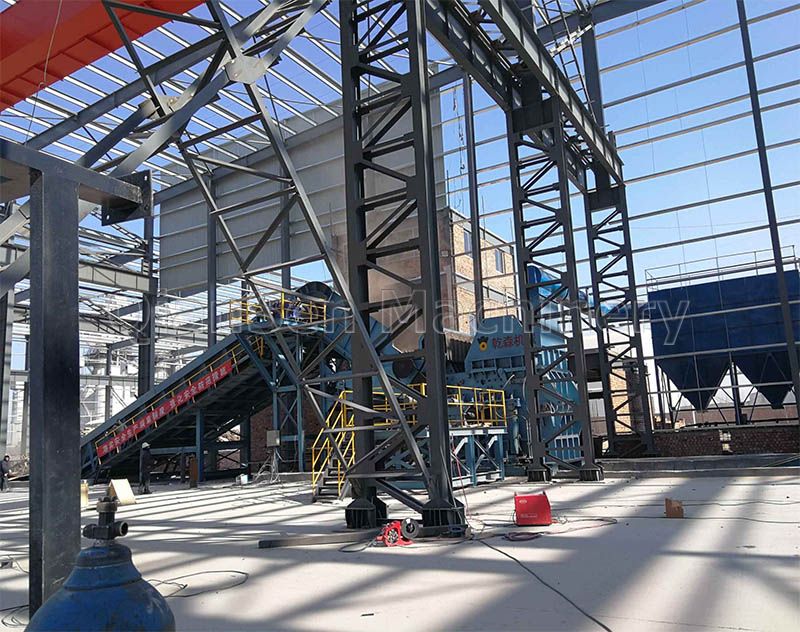

Many large industries are tasked with how best to dispose of accumulated scrap metal waste. Companies often choose to recycle the waste for further processing. The waste is usually sorted and then shredded to the desired size. This can be done at a recycling center or in-house and then sent to a recycling center. Using a heavy duty metal shredder machine such as the Qiansen metal shredder machine can convert the material into smaller pieces, making the disposal process much easier.

There are many benefits to pulverizing scrap metal, such as recycling, increased ease of disposal by saving space and reducing labor, increased remelting efficiency, and the elimination of contaminants from the metal to improve its quality and value.

Metal processing is an excellent application for low-speed pulverizing technology.Qiansen has many metal processing customers around the world.

Ferrous Metals

Common applications include: thin gauge sheet metal, tin roofing and siding, stampings, turned parts, molded parts, appliances and automotive panels (not complete vehicles). Shredders are commonly used to eliminate airspace, increase density, reduce transportation costs and improve pricing.

Aluminum

Sheet, tarnish tabbers, slit balls, coils, siding, HRB bales, wheels, profiles, radiators and more. In these applications, Qiansen pulverizers are widely used to process, release, densify and prepare material for sorting, paint stripping systems and furnaces.

Copper, brass, other non-ferrous metals

anodes, pipes, radiators, ICW, brass, silver-plated wire and plate have all been processed using the Qiansen pulverizer for release, recovery and densification prior to the furnace.

Metal shredder machine are Suitable for National Circular Economy Park, National Urban Mineral Demonstration Base, Scrap Steel Processing and Distribution Center(base), Steel and Nonferrous Metals Industry, Scrap automobile dismantling and remanufacturing etc. Scrap Automobile Shell. Low-carbon Light Scrap or Mass, Scrap household appliances, etc remove the paint and other impurities through the Shredder System; and then sort out the ferrous metal, non ferrous metals, non-metallic objects through the sorting system; get density about 1.2t / m3 scrap shredder products.

Advantages of crushing material

1 Uniform size can achieve continuous feeding

2 High effluent rate, low impurity rate and reduced air pollution.

3 Stabilize the chemical composition of the steel water.

4 Lower content of phosphorus and sulfur in steel water

5 When mixing with other waste steel, the broken steel can fill the gap and increase the additive density.

6 The electrode damage decreases during smelting.

7 During smelting, the furnace is evenly heated and the life of the furnace is extended.

8 High melting efficiency, which can be effective and energy saving.

1. Our company implements tracking service for products. Pre-sale, sale and after-sales service for customers.

Pre-sales: guidance on equipment layout and equipment foundation;

On sales: guidance on the production, delivery, installation and commissioning technical services of the equipment;

After-sales: Customer daily maintenance, safety production and other services to ensure the normal operation of the equipment.

2.The warranty period for the equipment is 18 months after the arrival of the goods or 12 months after the acceptance (whichever comes first). During the warranty period, the user's fault feedback will be answered within 4 hours.Within China arrived at the customer site within eight hours, other countries to arrive at the customer site within 72 hours.

A.We will send you the spare parts by free if the problems caused by us.

B.If it is the men-made problems,we also send the spare parts,however it is charged.

C.About the purchased parts,Such like:Siemens(motor),SKF(bearing),Rexroth,They are multinational company, and they will have after-sale service points in your local , So you can enjoy global warranty service.

D.The daily loss of equipment provides customers with original parts and processing drawings, which is convenient for customers to choose.

RFQ:

1.Are you trading company or manufacturer?

We are the manufacturer, and We guarantee that under the premise of the same technical parameters and quality, we provide the most appropriate price.

2.How long is the delivery time?

For standard machines, it would be about 30 days; For non-standard machines and customized machines according to clients specific requirements, it would be about 45 days.

3.How to pay to you ?

We can negotiate about payment. Generally speaking, our practice is:T/T in advance. We can accept 30% deposit , and balance paid to us before delivery.

4.Where is your factory located? How can we visit there?

Our factory is located in Xinji City, Hebei Province, China, you can fly to Shijiazhuang Zhengding international airport or Beijing Capital International Airport or Shanghai Pudong International Airport,then we pick you by car.Welcome to our factory at any time.

5.How does your factory do regarding quality control?

we are the manufacturer of this kind of shredder for more than 10 years,our customers all over the world, we have rich experience on production and R&D,: All products have to pass strict inspection before delivery. We have gained ISO9001:2008 authentication and Eu CE certification,if you need other certificate and quality control,please contact us.

6.Do you have inspection procedures for machines?

100% self-inspection before packing

7.All products can be customized?

All products can be customized by our team of professional designers.

8. How can i get the after-service?

A. We provide one year guarantee and lifelong maintenance.

B.We will send you the spare parts by free if the problems caused by us.

C.If it is the men-made problems,we also send the spare parts,however it is charged.

D. Any problem, you can call us directly.Anna:86 15930888103(WhatsApp/Wechat)

| Model | Type of main engine | Feed Opening Width(mm) | Main Motor Power(kw/HP) | Feed Quantity(T/H) |

| PSX-1450 | PSJ80104 | 2500 | 1450KW/2000HP | 30-40 |

| PSX-1600 | PSJ80104 | 2500 | 1600KW/2200HP | 35-45 |

| PSX-2240 | PSJ80104 | 2500 | 2240KW/3000HP | 40-50 |

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Metal Shredder Crusher

Copyright © Xinji Qiansen Environmental Protection Technology Co.Ltd All Rights Reserved | Sitemap | Powered by